Review of Common Practices in Arresting of Airborne Viruses in Work Place in Sri Lanka

By Eng. Ruwan NagahawatteIntroduction

COVID 19 virus has done immeasurable damage to the human population on this planet in terms in all sectors of life. Today countries in this world are socially, financially, and culturally apart than in any time in human history. Pre-COVID era was dominated through connectivity of countries for their needs in food, cloths, shelters and technology. With the fast spread of Corona virus, countries and regions in the world had imposed restrictions on human activities in regional level and global levels to control the spread of virus. However the shutdown to control unprecedented demand of health services had disrupted the total livelihood of entire human race. Engineering community has broader responsibility in ramping up with invention and production of lifesaving equipment and services for the recovery human health and finding ways to operate workplaces and keep essential services of Water, electricity, petroleum and telecommunication running for sustenance of daily life of humans.

Manufacturing sector in a country has the most responsibility in this endeavor in restoring the supplies. However the use of humans in conditioned air space on confined area against an airborne virus has been the greatest challenge for services engineers in modern era. Today, the managements of organizations are approached by many marketing teams with claims of their products in combating the airborne virus. This article intended to review technical understanding in to the common practices in Sri Lanka and discuss the factors of effectiveness.

Generally adaptation of following main practices can transform any workplaces into safe working environment.

- Monitoring of employees health on regular basis and isolation of suspected cases

- Use of Personal Protective Equipment for employees

- Adaptation of air filtration systems

- Implementation of Air disinfection system

- Regular surface disinfections

- Mechanical Air Filters

- Membrane type high efficiency particulate air filters

- Ultraviolet Energy Devices

- Bipolar Ionization/ Corona Discharge/ needle point Ionization

- Minimum target UV dose of 1500 j/cm2

- Moving air stream of 2.5 ms-1

- Minimum irradiance zone of 600mm

- Minimum UV exposure of 0.25 seconds

- In room air Cleaner Guidance for Reducing COVID 19 in Air in your Space/Room- By ASHRAE 21/01/2021

- ASHRAE Epidemic Task Force – Filtration and Disinfection – 20/10/2020

However as engineers, we have key responsibility in implementing in item 3 and 4 of above methods in our workplaces.

Air Filtration

Mechanical air filters consist of specially designed membranes or porous structure of fiber that can trap particles of higher sizes (greater than the filter membrane size). Air filtration in modern air conditioning systems can be mainly described under following applications

However it is important to understand that the size of filtration membrane and fraction of particles removed from air passing through the filter are most important parameters in any air filtration component. Generally the Minimum Efficiency Reporting Value (MERV) is widely used as common indicator to monitor the performance of the filtering devices

What it the Minimum Efficiency Reporting Value (MERV) for Selection of Filters

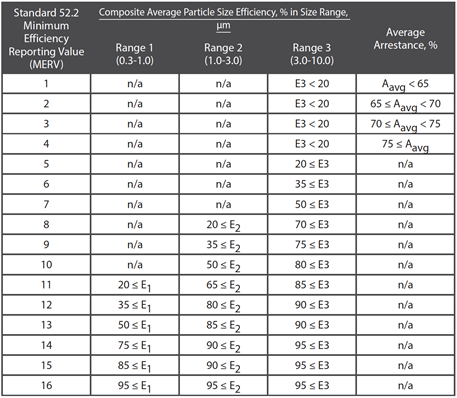

The MERV is a single number that is used, along with the air velocity at which the test was performed, to simplify the extensive data generated by the method of testing. MERV is expressed on a 16-point scale and is derived from the Particle Size Efficiency for each of the three groups.

Table 1 : MERV Parameters

Table 1 : MERV Parameters

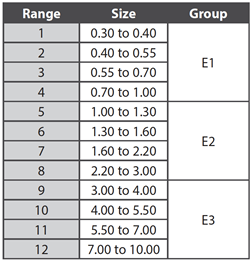

Table 2 : Particle Size Ranges

Table 2 : Particle Size Ranges

Airflow Rates for Filter Selection

The Minimum Efficiency Reporting Value (MERV) must be stated with the air velocity at which the filter was tested. For example, if the filter was tested with an air velocity of 2.5 m/s and was found to be MERV 8, the filter’s Minimum Efficiency Reporting Value would be MERV 8 @ 2.5 m/s. ASHRAE Standard 52.2 tests are to be conducted at one of seven airflow rates: 0.6m/s, 1.25 m/s, 1.5m/s, 1.9m/s, 2.5 m/s, 3.2 m/s, and 3.8 m/s.

Minimum Final Resistance

The minimum final resistance shall be twice the initial resistance, or as specified. The choice of final pressure drop will change the dust holding capacity and possibly the arrestance such that care should be taken in comparing values.

Effect of Humidity

Filter performance is highly affected with humidity level of air volumes. Generally the filters are tested at 35% - 55%. Change of humidity will create additional resistance on the airflow.

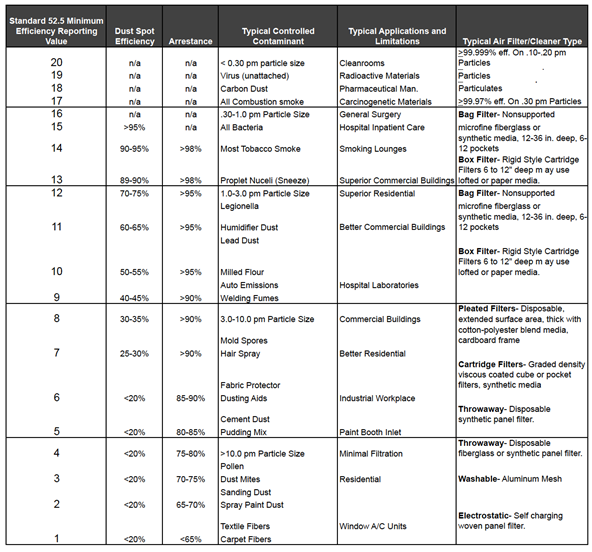

Table 3 : Air Filter Selection Guide

Table 3 : Air Filter Selection Guide

High Efficiency Particulate Air Filters (HEPA filters)

Generally true HEPA filters are capable of arresting up to 0.3 m-median diameter particles with minimum of 99.97 % efficiency. HEPA filters are normally having a MERV more than 16 and represent highly efficient filter class.

The filtrations devices in HEPA range generate high-pressure drops across the filter and normally not suitable to be retrofitted in to HVAC systems that was not design for high-pressure losses. Also it is impotent to note when HEPA filters are introduced in to an existing HVAC system, the new filter assembly should be sealed properly so that there is no leakage of flow from upstream to the downstream. Also HEPA filters are very fragile and need to be handled with extreme care during installation and servicing to prevent damages to the filter.

Air Disinfective Systems

Air disinfective system has primary function of find and eliminate the virus, bacteria and harmful elements in the air. Generally following systems are very common in cleansing the air volumes in workplaces.

Ultraviolet Energy

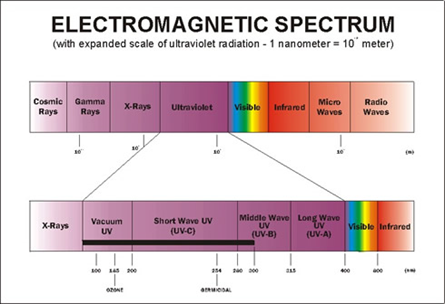

Figure 1 : Electromagnetic Spectrum

Figure 1 : Electromagnetic Spectrum

Ultraviolet waves represent waves having wavelength of 400 to 10 nanometers in electromagnetic spectrum. It is found that the energy carried by the ultraviolet waves in electromagnetic wavelength can be used to inactivate viral, bacterial and fungal organisms to the level that they could not replicate and potentially spread the diseases.

Figure 2 : UV lights used in ducted air system

Figure 2 : UV lights used in ducted air system

Although the entire UV spectrum is capable of inactivating the microorganisms, it is found that 100- 280 nm being effective in dealing with germicidal effect and 265nm is the most ideal wavelength. Today most of the UV lights manufactured to work on 253.7nm wavelength.

Any UV disinfection system to be effective it should have to maintain following characteristics

It is also important to note that, generally UV disinfection needs to couple with mechanical filtration having minimum of MERV 8 for dust filtration.

Bipolar Ionization/Corona Disinfection/Needle Point Ionization

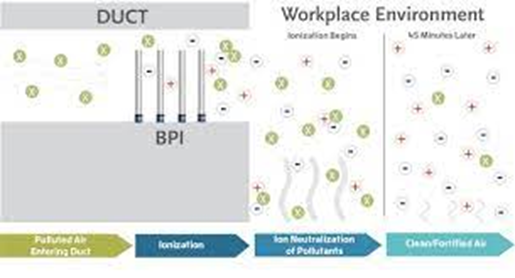

Bipolar Ionization/Corona Disinfection/Needle point ionization is a air cleaning method that uses reactive ions and/or reactive oxygen species to come in contact with microorganisms and inactivating them from spreading the diseases. In this technology, it uses the high voltage electrodes to create reactive ions in air that react with airborne contaminants.

Figure 3 : Bi Polar Ionization working principal

Figure 3 : Bi Polar Ionization working principal

Generally the equipment designs consist of generation of mixture of reactive oxygen species, ozone, hydroxyl radicals and superoxide ions. Systems of this nature has been found with comments of totally ineffective to the very effective in reduction in airborne particles and acute health symptoms.

Unlike other technologies yet the datums of required ionization load in passing area to inactivate the microorganisms , retention time for ions to engage with microorganisms and best air velocity is not established by independent approving body in this technology. Further the effect of leaking ionized air into the breathing zone and its long terms effects are not studied in details.

Most importantly, significantly rigorous, peer-reviewed studies do not currently exists on this emerging technology for measure the effectiveness. Hence manufactures data should be carefully considered before implementing these systems with proper performance evaluation criteria.

References

Eng. Ruwan Nagahawatte

Eng. Ruwan Nagahawatte

.Sc. Eng. (Hons), C.Eng. MIESL

Eng. Ruwan Nagahawatte, a Mechanical Engineering graduated from University of Moratuwa. He had involved in planning and development of all Waste to Energy projects in Sri Lanka. He had carried out the initial technical feasibility studies for Municipal Solid Waste Disposal project at Meetotamulla and conducted full feasibility study in proposed development projects at Karadiyana and Gampaha. He is a registered consultant in Colombo Municipal Council and Sustainable Energy Authority of Sri Lanka for development of Municipal Solid Waste management and disposal systems.